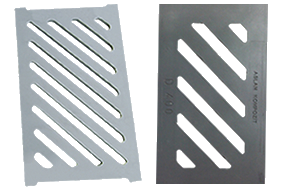

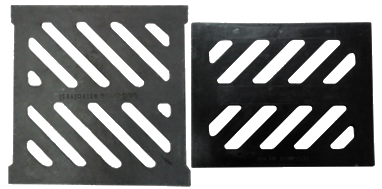

COMPOSITE GULLY GRATING

|

MC_202.01

|

Gully Grating

|

200

|

500

|

17

|

|

B125-125KN 12,5 TON

|

|

MC_202.02

|

Gully Grating

|

300

|

500

|

35

|

|

B125-125KN 12,5 TON

|

|

MC_202.03

|

Gully Grating

|

300

|

500

|

45

|

|

D400-400KN 40 TON

|

|

MC_202.04

|

Gully Grating

|

400

|

500

|

45

|

|

D400-400KN 40 TON

|

|

MC_202.05

|

Gully Grating

|

500

|

500

|

45

|

|

C250 / D400

|

|

MC_202.06

|

Gully Grating

|

500

|

500

|

60

|

|

D400-400KN 40 TON

|

• Composite gully gratings, can have special logo, has a wide range of color options.

Advantages of Composite Gully Grating

-

Tight and consistent part tolerances. (Dimensional Stability)

-

Excellent electrical (insulating) properties. (Electrical Properties)

-

Resistant to withstand the demanding tests. Corrosion resistance in aggressive environments, including solvents. (Corrosion & Chemical Resistance)

-

A part made of composites can typically be up to 25-30 per cent lighter than an equivalent steel part. (Weight Reduction)

-

High mechanical properties (strength, stiffness and impact), good strength/stiffness weight performance. (Mechanical Properties)

-

Designers may combine functions in a single .Lower part costs and tooling costs. Design flexibility, thin to thick variable component sections (not with class A parts). (Design Flexibility)

-

Can be mass colored (pigmented) to match customer specification. (Pigmentation)

-

Surface profile identical to a steel or aluminum panel, online painting state-of-the-art. (Class A Surface)

-

Non-melting, no droplets, no dripping, keeps its structural integrity, flame retardant, low smoke density, low toxicity and no halogens. (Fire & smoke)

-

The HDT (heat distortion temperature) is higher. Low thermal conductivity. (Thermal Resistant)

-

Inserts can be integrated in the molding process. (Different Materials can be Inserted)

-

Project costs are lower with composite, speed to market is faster than with steel stampings because fewer tools are needed. (Faster to market)

-

Composite materials can be as transparent as glass. (Transparency Property)